-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

- burster

- Sensors

- Displacement sensors

- Digital Indicator 9163

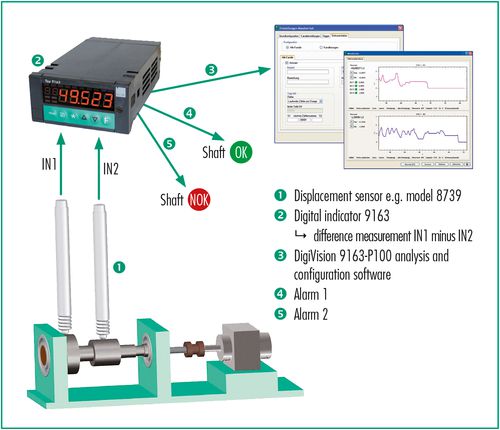

Digital Indicator 9163 Digital Indicator

Single-channel or multi-channel version for strain gauge, potentiometer, norm signals, Pt100 and TC

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- For force, pressure or torque measurements using strain gauge sensors

- For position or angle measurement using potentiometric or DC/DC sensors

- For temperature measurement using Pt 100 sensors or thermocouples

- Optional multi-channel model

- Optional PROFIBUS or serial interface

- 0.1 % measurement accuracy plus sensor-specific linearization

- Range of mathematical functions (e.g. differential measurement)

- OK/NOK feedback on multi color display and via 4 alarm limit outputs

- High sampling rate (500/sec.)

-

Product data

Model 9163 Measurement accuracy 0.1 % F.S. Sample rate 500/s Type of sensor - Strain gauges

- Potentiometer

- Standard signals

- DC/DC

- Transmitter

- Temperature sensor

- Thermocouple

Interfaces - RS232

- RS485

- PROFIBUS

Indicator 5 digit, dual-color red/green Sensor excitation Strain gauge:

- 5 / 10 V / 60 mA

Potentiometer:

- 2,5 / 5 / 10 V

Standard signal, DC/DC:

- ± 60 mV, ± 100 mV, ± 1 V, ± 5 V, ± 10 V

Transmitter:

- 15/24 V / max. 150 mA

Protection class IP54 Supply voltage 100 - 240 VAC / 50 - 60 Hz, 20 - 27 VAC/VDC

Measurement channels 16 Specific characteristics - For force, pressure or torque measurements using strain gauge sensors

- For position or angle measurement using potentiometric or DC/DC sensors

- Optional multi-channel model

- Range of mathematical functions (e.g. differential measurement)

- OK/NOK feedback on multi color display and via 4 alarm limit outputs

-

Description

The 9163 process value indicator covers a wide range of applications in which process values need to be measured, displayed, analyzed and transferred to higher-level control systems. Typical applications include measuring geometric values in production, for instance differential measurements, or testing material properties in the laboratory.

The measured values can be transferred via PROFIBUS, RS232 interface or analog output.

The multi-channel version can be used with up to four sensors. These sensors can be combined using mathematical functions, so that even complex measurement tasks can be performed with just the one instrument.

Visual alarms on the display make it easier and more convenient to assess when values lie off-limits. Up to four configurable outputs are available as relay or logic outputs.

The excellent measurement accuracy of 0.1% also makes this instrument suitable for high-precision applications. Two digital inputs are provided for controlling various functions such as Reset or HOLD.

Strain gauges, potentiometric sensors, transmitters with process value output, Pt100 and thermocouples can be connected directly to the process value indicator. Thanks to its manual linearization facility, the instrument can handle sensors with a huge range of characteristic curves.

The latest microprocessor technology has been used to pack a huge amount of engineering into the minimum space. Essential device settings can be made via the six-button keypad. Permanent settings such as the choice of excitation voltage are made using jumpers. The large 13 mm high, 7 segment display ensures that measurements and menu parameters can be read clearly.

The integral excitation voltage source supplies the sensors and provides the auxiliary power for any transmitters that are connected. The manual linearization facility with 32 data points means that even non-linear sensor curves can be input.

The indicator also supports memory functions for min, max and peak-to-peak values. The high measurement rate of 500 readings/s also ensures a rapid response by the four built-in alarm limit relays. TTL switched outputs can be provided as an alternative option. The device settings can be configured via the keypad or the optional RS232, RS485 or PROFIBUS interface.

A GSD file is supplied as standard with the PROFIBUS option for PROFIBUS integration.

A powerful software tool for data analysis and documentation is available on request for use with the RS232 and RS485 options.

-

Data Sheet & Downloads

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.