-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

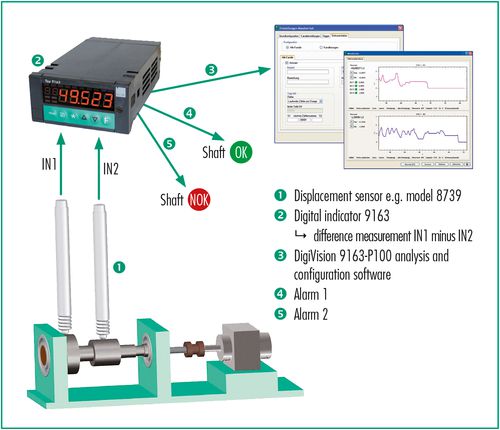

8739 LVDT transducer with IN-LINE amplifier

Small sensor with a diameter of only 8 mm for installation into restricted structures, vibration-proof and wear resistant, internal IN-LINE amplifier, for direct measuring of displacement and indirect measuring of convertable mechanical values

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Ranges from 0 … 1 mm to 0 ... 25 mm

- Non-linearity 0.25 % F.S.

- Sensor diameter 8 mm

- Vibration and wear free

- Output 0 ... 10 V

- Optional output 0 ... 5 V, ± 5 V, 4 ... 20 mA

- Sensor with or without IN-LINE amplifier

-

Product data

Model 8739 Principle Inductive Measuring range 0 … 1 mm

0 … 2 mm

0 … 5 mm

0 … 10 mm

0 … 25 mm (without return spring)Signal output 0 ... 10 V

0 ... 5 V

±5 V

4 ... 20 mA

10 ... 0 V

5 ... 0 V

LVDTProtection class IP60 Range of operating temperature -20 ... +80 °C Excitation voltage 13,5 ... 28 VDC Electrical connection Shielded PVC cable

Return spring Yes Options None

With threaded sleeve M12 x 1.75

Tip not gluedSpecific characteristics - Sensor diameter 8 mm

- Vibration and wear free

- Sensor with or without IN-LINE amplifier

- Optional protection class IP65

-

Description

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures.

Typical application fields are displacement and extension measurements on- Machines

- Servo systems

- Motor vehicles

- Test benches

- Production plants

The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

The transducer is constructed as a probe at which within the measuring range a spring pushes the probe tip towards the measuring object. Bellows protect the mechanical guidance of the probe tip against pollution and splash water.

The IN-LINE amplifier is integrated in the connector cable and adjusted specifically to the sensor. Both components form a unit while they can be separated for mounting purposes (miniature plug connection at the transducer). The use of not harmonized components may lead to increased measurement errors. For the IN-LINE amplifier version the sensor body is galvanically isolated from the excitation and from the measuring signal.

Lateral forces decrease the durability. -

Data Sheet & Downloads

-

Accessories

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

Wire

15.04. -

19.04.24 -

Düsseldorf,

40474,

Germany

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.