-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

- burster

- Sensor Electronics

- Digital Indicator

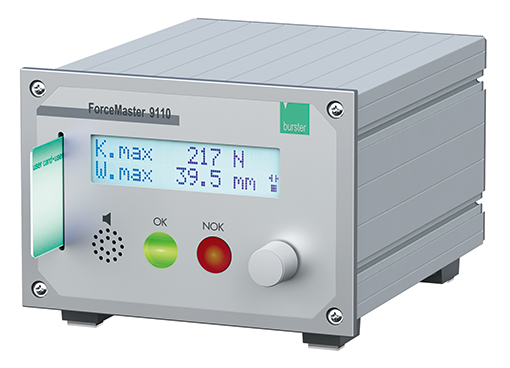

- ForceMaster 9110

ForceMaster 9110 Low-Cost hand lever presses monitoring

ForceMaster 9110 was developed to monitor hand lever presses. One button operation and data for different processes on PLC-slotcards allow every user quick changes of press fitting procedures. Attractive low cost device for precise quality monitoring.

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Excellent value "Plug & Work" complete system

- Easy auto-configuration with automatic setting of the evaluation tools

- Smart Card system for manipulation free configuration and storage of settings

- Acoustic and optic error indication

- Data logging on USB stick (optional)

- PLC sequence control function (optional)

- Analysis and configuration software included

- Automatic sensor identification

- Hub and other component counters

-

Product data

Model 9110 Measurement channels 2 Max. amount of active measurement channels 2 Type of sensor - Strain gauge

- Potentiometer

Measurement accuracy < ± 2 % F.S. Fieldbus interfaces No Interfaces - USB

- RS232

Indicator 2 lines LCD display Sensor excitation 5 V Protection class IP20 Supply voltage 90 ... 240 VAC / 50 ... 60 Hz Automatic sensor identification Yes Autoconfiguration Yes Max. amount of measurement programs 1 Display - Numerical

Acoustic and optic error indication Yes Data logging Option Components counter Yes Specific characteristics - Excellent value "Plug & Work" complete system

- Easy auto-configuration with automatic setting of the evaluation tools

- Smart Card system for manipulation free configuration and storage of settings

- Acoustic and optic error indication

- Data logging on USB stick (optional)

- PLC sequence control function (optional)

- Analysis and configuration software included

- Automatic sensor identification

- Hub and other component counters

-

Description

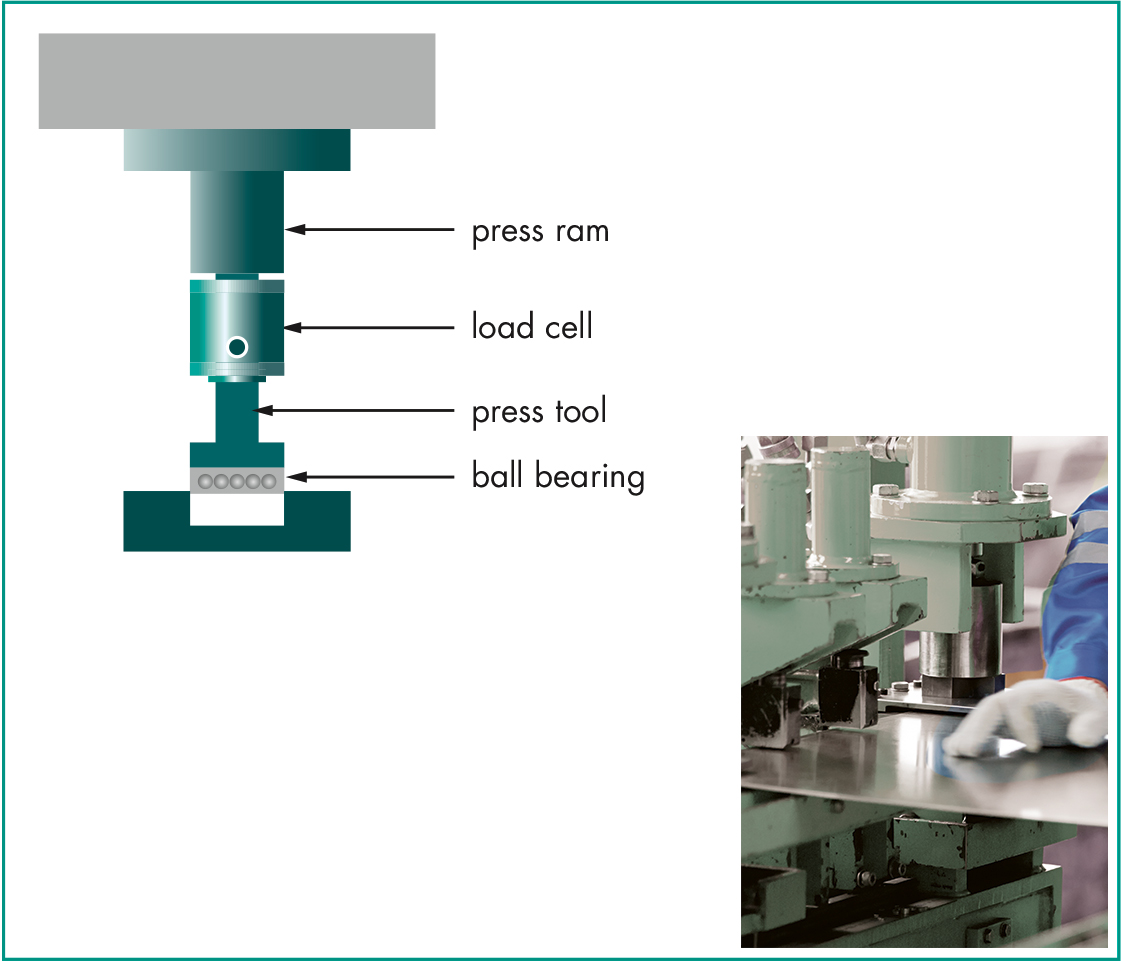

Pressure on price and quality continue to rise. The need to monitor even the simplest manufacturing and assembly process is increasingly common. With 100% monitoring of force/ time curves or force displacement/time curves, the Force- Master satisfies all requirements for ensuring the reliability of even simple press-fit processes. Thanks to its ultra-simple, single-button operation and intelligent auto-configuration, even semi-skilled staff can set up the equipment safely and quickly. "Card & Go" is the smart system that uses master, tool and PLC smart cards to make equipment settings, inhibit unauthorized changes and to trigger actions in sequence with the production process.

The ForceMaster 9110 has been developed specifically for monitoring manual lever presses. Simple manual workstations can be monitored extremely efficiently using the ForceMaster. Easy control functions that used to require an additional PLC can now be performed reliably with the ForceMaster. Tools can be changed quickly and easily using tool cards. The ForceMaster is used for example for- Pressing ball bearings

- Compressing powders

- Press-fitting pinion gears

The ForceMaster has a multi-voltage power supply. Excitation of the load cell and displacement sensor is provided by internal voltage-conditioning circuits. Sensor identification is built into the sensor plug, allowing sensors to be connected easily with no further configuration needed.

The integral auto-configuration tool uses a GOOD component to train the ForceMaster with the measurement curve and automatically set the evaluation elements. The user can make any further fine-tuning and adjustments to these settings manually if required.

Visual indicators such as a red and green indicator lamp signal "Good" or "Bad" parts. An audible sound is also output for "Bad" parts.

The built-in PLC function allows sequence control of up to 60 steps. This can be used, for instance, to control pneumatic cylinders, compressors for blowing out workpieces, and reject gates for OK/NOK parts.

The PC software, which is included free of charge can be used for measurement-curve analysis and fine-tuning the evaluation elements. It also lets the user view and archive the measurement curves recorded on the USB stick. -

Data Sheet & Downloads

Data sheetBrochureOperation manualPresentationSoftwareFurther info -

FAQ

How do I attach a load cell and a displacement sensor to a hand lever press?

<link www.youtube.com/watch _blank "external-link-new-window link-arrow" "Öffnet externen Link in neuem Fenster">Watch the video right here</link>

-

Videos

Please accept marketing-cookies to watch this video.ForceMaster 9110 - Low-cost hand lever presses monitoring

Please accept marketing-cookies to watch this video.How to do: Attach force and displacement sensor to a hand lever press

Please accept marketing-cookies to watch this video.Motek exhibition video burster 2015

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.