-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

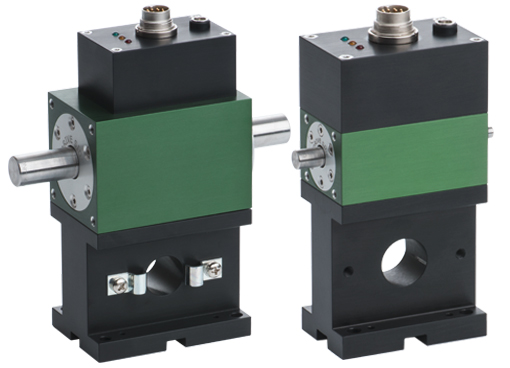

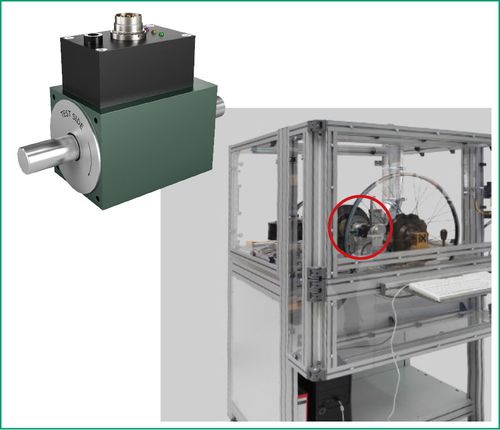

8661 Precision torque sensor

Measuring ranges from 0 ... 0.02 N·m up to 0 ... 1000 N·m, low linearity deviation of ≤ ±0.05 % F.S., intelligent operating state display, output signal 0 ... ±10 V (optional 0 ... ±5 V or USB), speed and angle measurement with resolution of up to 2000 increments (option), excellent price performance ratio

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measuring range from 0 ...0.02 N·m to 0 ... ±1000 N·m

- Low linearity deviation of ≤ ±0.05 % F.S.

- Intelligent operating state indicator

- 16 bit D/A converter including digital adjustment

- Output signal 0 ... ±10 V (optional 0 ... ±5 V or USB)

- Speed and angle measurement with resolution of up to 2000 increments (option)

- Excellent price-performance ratio

-

Product data

Model 8661 Principle Rotating Measuring range 0 … ± 0,02 N·m

0 … ± 0,05 N·m

0 … ± 0,1 N·m

0 … ± 0,2 N·m

0 … ± 0,5 N·m

0 … ± 1 N·m

0 … ± 2 N·m

0 … ± 5 N·m

0 … ± 10 N·m

0 … ± 20 N·m

0 … ± 50 N·m

0 … ± 100 N·m

0 … ± 200 N·m

0 … ± 500 N·m

0 … ± 1000 N·mSignal output 0 ... ±10 V

USB

0 ... ±5 VRatio No dual-range

1:10

1:5

1:4Mechanical connection Round shaft

KeywayElectrical connection - 12 pins plug connection

- USB

Integrated speed measurement Option

(TTL output signal with 400 or 1024 increments)Integrated angle measurement Option

(TTL output signal with 400 or 1024 increments; angle resolution 0.225° or 0.09° with four-edge decoding)Multiple range Ratio 1:4, 1:5;

1:10 for measuring range 0 … 5 N·mIncrements on encoder disk No encoder disk

240

400

1024

2000Protection class IP40 Range of operating temperature 0 ... +60 °C Max. rotary speed Depending on measuring range 7 000 - 25 000 1/min Signal transmission non-contact Specific characteristics - Low linearity deviation of ≤ ± 0.05 % F.S.

- Intelligent operating state indicator

- Speed and angle measurement with resolution of up to 2000 increments (option)

- High performance software (option USB) including mechanical power computation, multichannel operation, freely editable mathematical auxiliary channel

- Excellent price-performance ratio

-

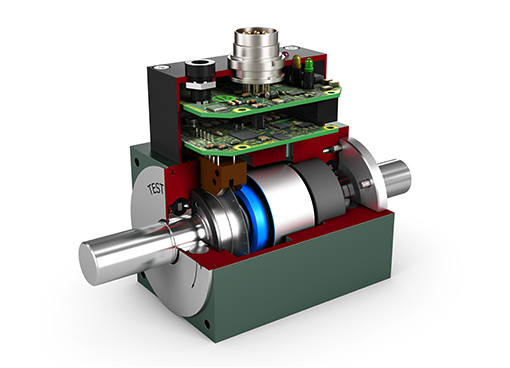

Description

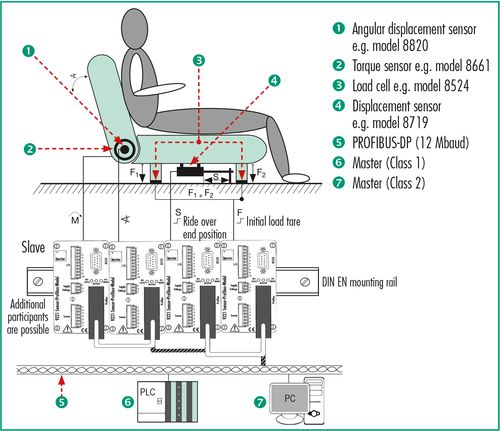

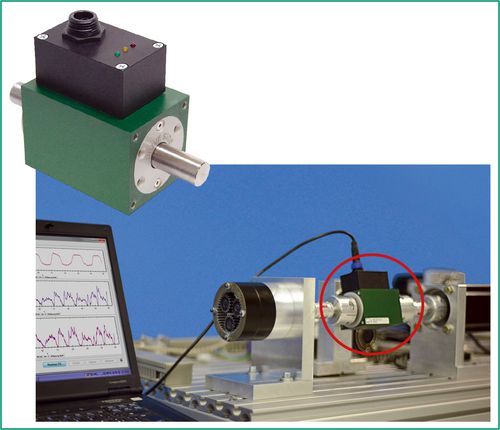

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques.

An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface. A laptop or PC running the DigiVision PC software can read, visualize and archive the measurement data. System integration, for instance into LabView, is easy thanks to a driver package available free of charge.

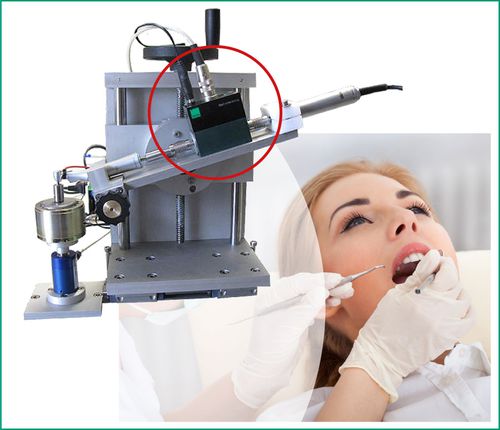

► Test setups for precision mechanics

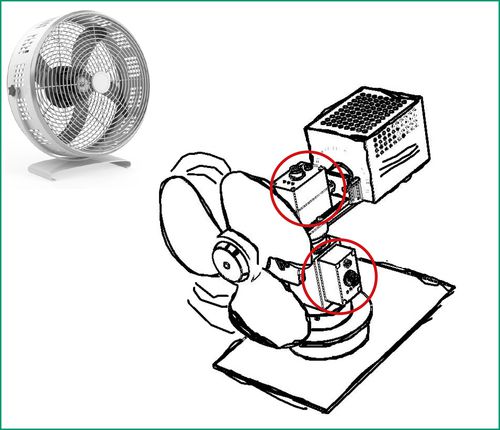

► Haptics testing of actuator elements

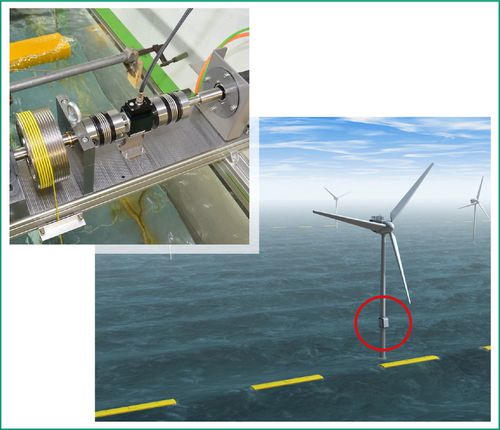

► Engine test benches and power measurement

► Biomechanical product testing

► Measurement of bearing friction torques

► Suitable for use in all types of test benchThe 8661 torque sensor essentially consists of three blocks: the rotor, the housing (containing the stator) and the output electronics. The rotor is composed of several parts and contains the actual measuring device - a spring element. This spring element is designed to deform elastically under an applied torque. This results in torsion, which in turn pro-duces a very small amount of strain in the material of the measuring element. Within certain limits, this strain is linear and proportional to the applied torque. It can be measured using strain gauges, which are connected in a Wheatstone bridge circuit. A microprocessor conditions the signal from the Wheatstone bridge and transfers it to the stator. The rotor is linked to the stator via two ball-bearings, and signal transfer is contactless. The stator contains the electronics needed to supply the rotor with the required operating voltage by inductive and contactless means. In the opposite direction, it receives the optically transmitted, digitized torque signal and routes this signal to the output electronics. Here it is converted into an analog 0…± 10 V output signal, which is output via the connector. Alternatively, the sensor is available with a USB port. The 8661 torque sensor can optionally be fitted with an incremental encoder disk for measuring the speed and angle. This disk has 2000 increments, allowing angular resolutions of up to 0.045° by means of four-edge decoding. Three LEDs indicate the sensor operating status for simple diagnostics. Speeds of up to 25,000 min-1 can be measured depending on the selected measurement range and optional incremental encoder disk.

-

Data Sheet & Downloads

Data sheetBrochureOperation manualSoftwareFurther info -

Accessories

-

Videos

Please accept marketing-cookies to watch this video.Torque Sensors: Made in Germany - Made by burster

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

Wire

15.04. -

19.04.24 -

Düsseldorf,

40474,

Germany

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.