-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

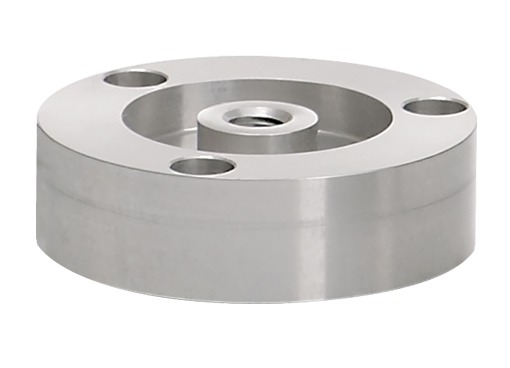

8523 Tension and compression load cell

Compact, robust, easy handling, for static and dynamic measurements, high-strength aluminium, exceptional low price

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measuring ranges from 0 ... 20 N to 0 ... 5 kN

- Tilt-free installation thanks to point-contact mounts

- Excellent price/performance ratio

- Easy mounting

- burster TEDS optionally available

-

Product data

Model 8523 Measuring range 0 … 20 N

0 … 50 N

0 … 100 N

0 … 200 N

0 … 500 N

0 … 1000 N

0 … 2000 N

0 … 5000 NDirection of force Tension and compression Standardization Option Signal output 1 mV/V nominal from 0 … 20 N to 0 … 50 N;

1.5 mV/V standardized from 0 … 100 N to 0 … 5000 NProtection class IP52 for measuring ranges ≤ 0 ... 500 N

IP64 for measuring ranges ≥ 0 ... 1000 NOverload protection No Pull-plate Option Load introduction button Option Range of operating temperature -30 ... +80 °C Specific characteristics - Measuring ranges from 0 ... 20 N to 0 ... 5 kN

- Tilt-free installation thanks to point-contact mounts

- Excellent price/performance ratio

- Easy mounting

- burster TEDS optionally available

-

Description

The tension & compression load cells from the 8523 series are designed for a wide range of uses. The sensors feature many benefits, including three point-contact mounts for tilt-free installation. Thanks to this feature, excellent measurement results can be achieved even with a sub-optimum mounting surface.

The force to be measured is applied to the central threaded hole in the tension or compression direction. For measuring purely compressive loads, using load buttons from our accessories range saves the need for complex sensor-integration mechanisms. Tensile loads in rods or chains can also be detected with ease using the optional pull plate.

Inside the sensor is an elastic membrane, on which are applied strain gages connected in a full Wheatstone bridge. If a tensile or compressive load is applied to the sensor, the ohmic resistance of the measuring bridge changes and detunes the output signal in proportion to the measured load in mV/V.

-

Data Sheet & Downloads

-

Accessories

-

Videos

Please accept marketing-cookies to watch this video.Example showing load cell fitted under pre-load with extreme overload protection

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.