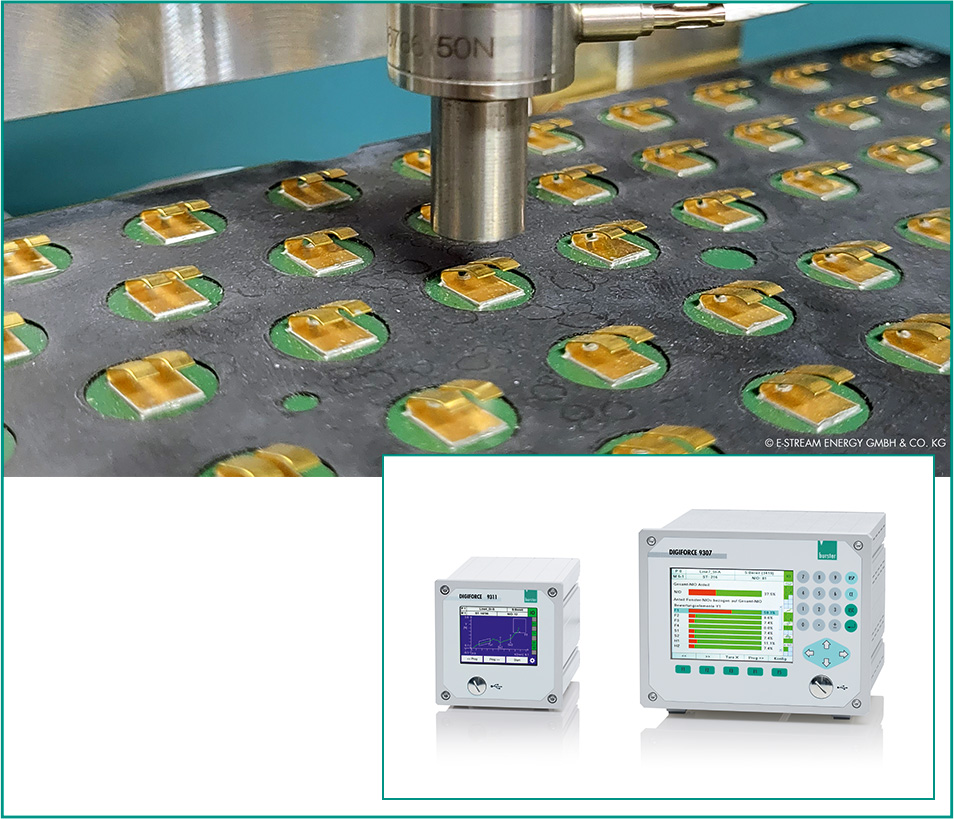

Quality Testing of Spring Contact based Backplanes

for Battery Energy Storage Systems

- Dynamic measurement of force/displacement characteristics with OK/NOK monitoring

- Integration into full automation via universal fieldbus interfaces such as PROFINET

- Up to 128 measurement programs for flexible type management

Task

As an alternative to fixed-contact power rails and busbars, backplanes with spring contacts enable individual testing and replacement of a battery’s cells. Dimensional accuracy and spring characteristics are critical to the quality of such contacts, so 100 % checking has to be carried out on each contact terminal.

Special Features

- OK/NOK testing with high accuracy for force and displacement channels

- Acquisition and transmission of quality-relevant parameters spring rate, hysteresis and contact spring initial height h0

Lösung

By means of an automatic X/Y positioning unit, each spring contact is positioned under an electrical linear actuator with a 8431/32 strain gage force sensor mounted on the front end, and a test stroke is initiated orthogonally to the spring contact. Depending on the design of the spring contact, a test stroke of typically only < 1 mm compression is performed within the permissible elastic spring deflection. The DIGIFORCE® 9307/9311 process monitoring can record the quality-relevant parameters of initial height h0, spring rate and hysteresis, and check them for compliance with tolerance specifications. An OK/NOK evaluation and measured values for reporting are made available at various interfaces.

Go to product DIGIFORCE® 9307

Go to product 8431, 8432

Sectors