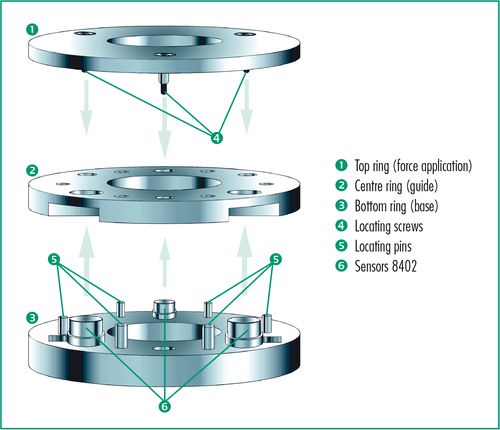

Custom-made annular sensor

created using three miniature compression load cells

- Optimum adjustment to given conditions

- Variable measurement range of complete system

- Implemented using standard products

TASK

In the custom machinery sector, special annular load cells are sometimes needed that have a large internal diameter in order to accommodate bulky workpieces or tools. Usually the quantities required are too low for it to be economic to produce a short run of custom sensors.

SPECIFIC REQUIREMENT

- Standardized output signals for analysis of sensor results by a measuring instrument

- Technical solution using standard products

- Rigid and compact system

SOLUTION

Three burster 8402 miniature load cells are mounted on a base ring of the required internal diameter, spaced apart by 120°. The sensors are held in their position in the plane by a guide ring, which fits around the sensors with sufficient clearance and is connected to the base ring by locating pins. The force is applied via a third, through-hardened ring, which is connected to the two other rings by locating screws. Conical spring washers are inserted beneath the screw heads to provide a stable initial load throughout the assembly. The burster 9243 instrumentation amplifier can be used to provide excitation for the three sensors and to output a summated value of their measurement signals. The complete assembly therefore looks and behaves like one sensor and can also be calibrated as such. Apart from price, there are further reasons for favouring this solution:

- It takes far less time to manufacture the three rings than to produce a custom sensor.

- Since the sensors are all standard components, there is a guaranteed ready supply of spare parts.

Sectors

Downloads