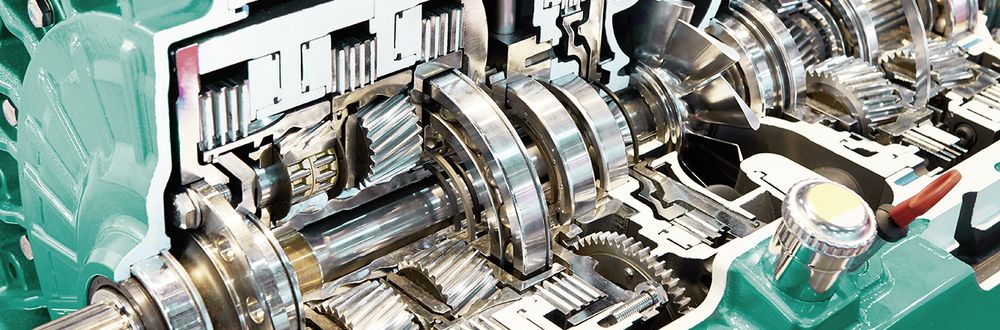

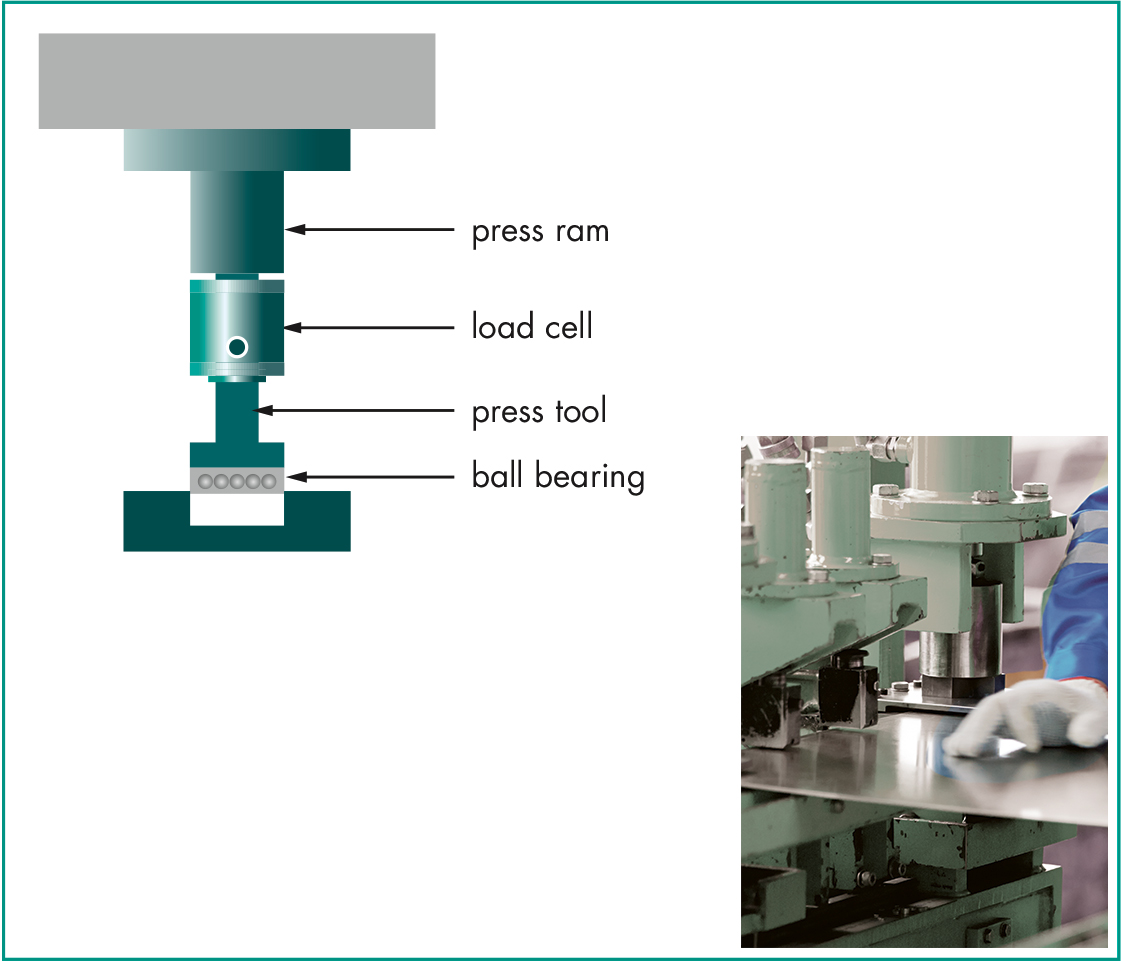

Monitoring the press-insertion force

of a ball bearing

- Comes in a range of peg and hole diameters

- Standard tool holder, suitable for retrofitting

- 5-fold protection in event of temporary static overloads

- Protected against ingress of coolant or lubricant

Task

A ball bearing needs to be press-fitted into a component. Load cell 8552 is used to verify that the bearing has been fitted with the correct force. The sensor can be fitted easily between tool and press ram using a standard tool holder. A visual and acoustic signal from the ForceMaster 9110 is used to indicate that the maximum force has been reached. The load cell is equipped with burster TEDS, so that sensor settings can be imported into the ForceMaster 9110 without any laborious configuration.

Watch our How-to-do video at: <link http: www.youtube.com burstervideo _blank external link in new>www.youtube.com/bursterVideo

Go to product

Go to product ForceMaster 9110

Sectors