Motor testing

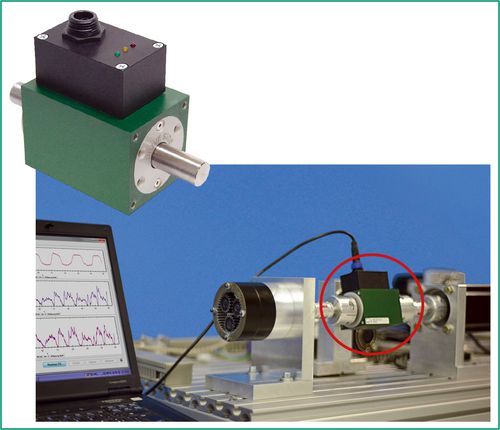

fast dynamic response, low torque, reliable measurement

- Plug&Measure software system with auto-scaling function

- Quick to put in operation

- Mathematical formula editor

- Numerical or graphical display of results

- Free driver package can be used for interfacing with LabVIEW or for integrating custom software

- Dual-range sensor

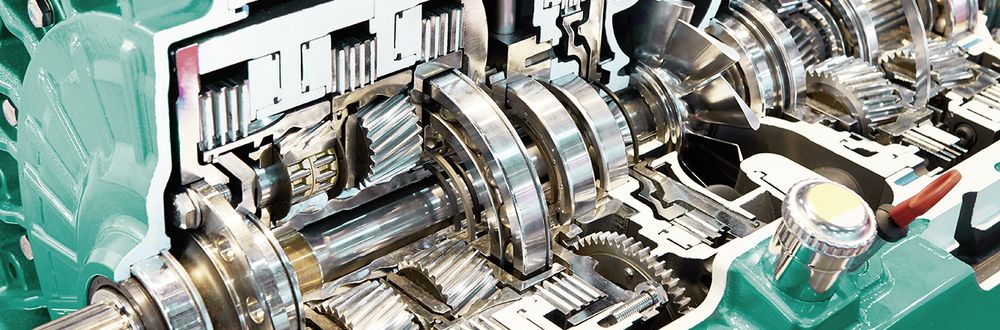

TASK

Miniature electric motors need to be intensively tested after final assembly in serial production to assess their electromechanical properties. This testing involves measuring torque and speed to assess subsequent mechanical power values. The test setup is required to provide high levels of precision, straightforward measurement-signal processing and overload protection.

SPECIFIC REQUIREMENT

- Rugged design

- Strong overload protection

- High reproducibility

- Low moment of inertia

- Measurement data available in digital form

- Two separately calibrated measurement ranges

SOLUTION

The low torques in this application mean that the measurement range must be chosen to achieve the necessary accuracy and overload protection.

The dual-range model of the 8661 torque sensor is permanently mounted between two full couplings: between sensor and drive and between sensor and transmission arm. These couplings are designed to correct vertical and angular misalignments and differences in length.

The torque and speed measurement signals are output via the built-in USB port for further processing. The DigiVision software, which is included with the sensor, can be used not only to capture, visualize and archive the measurement data but also to calculate the mechanical power.

Go to product 8661

Go to product DigiVision

Sectors

Downloads