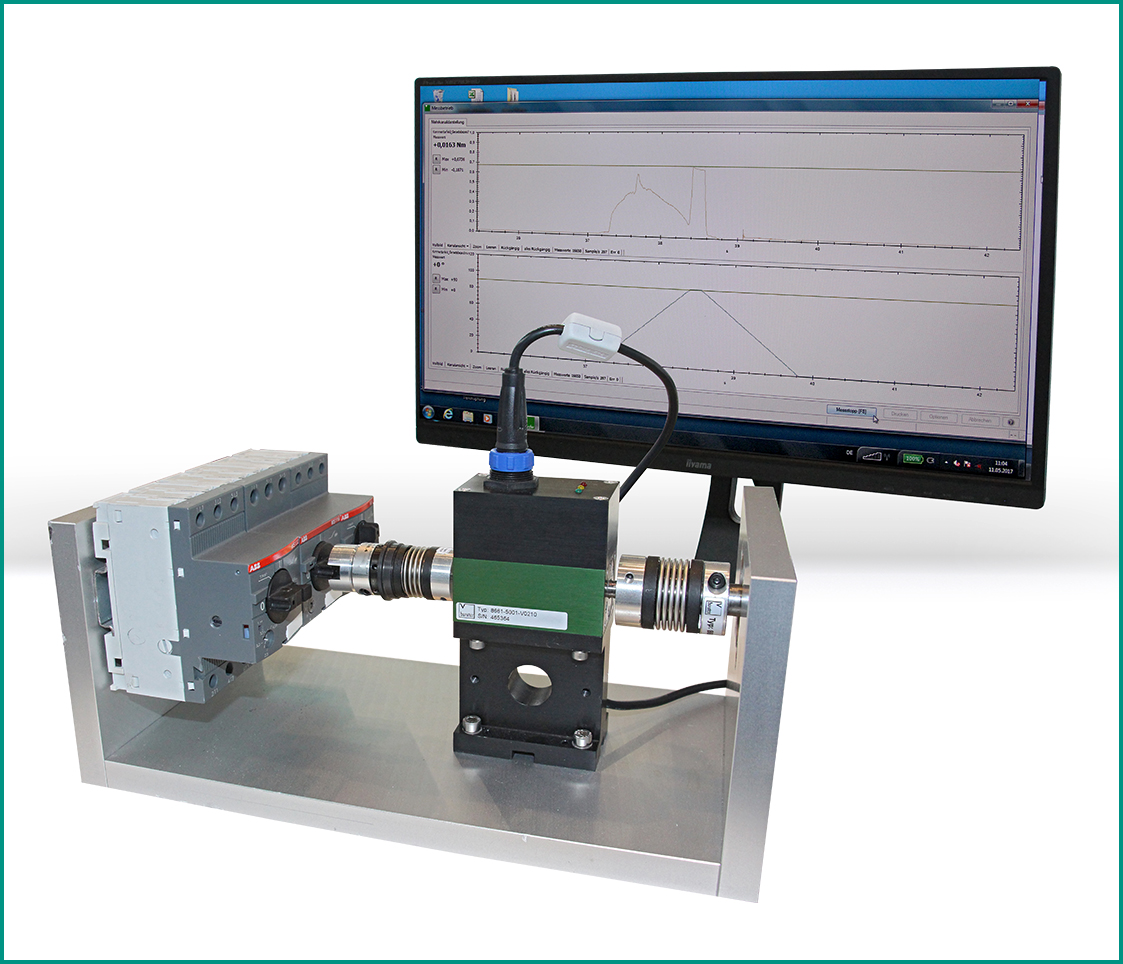

Testing motor starters

- Integral angle measurement

- Linearity error as low as 0.05 % F.S.

- DigiVision Plug & Measure PC software supplied as standard

- LabVIEW interface or alternative driver package for integrating in-house software available at no extra cost

- Dual-range sensor

Task

Actuation torques of motor starters need to be recorded during serial production. The aim is to log consistent product quality over a prolonged period. This requires storing raw data in a file that can be accessed later for analysis. Anything blocking the toggle switch can result in inadmissible spikes in the torque.

Specific Requirement

- Continuous storage of measured values

- High measurement accuracy with low linearity error

- A faulty end product can cause overload

Solution

Precision torque sensor model 8661 is selected because of the need for high measurement accuracy and a PC interface. The DigiVision PC software stores the measurement signals in their raw, unprocessed form, so that they can be accessed later by analysis software. The user is provided with both the torque signal and the angle signal. This association is important in helping to identify any faults in the product under test. An adjustable safety coupling is used to prevent damage to the torque sensor 8661 in the event of an overload caused by obstruction of the toggle switch. This coupling not only provides protection but is also able to correct any misalignments.

Sectors

Downloads