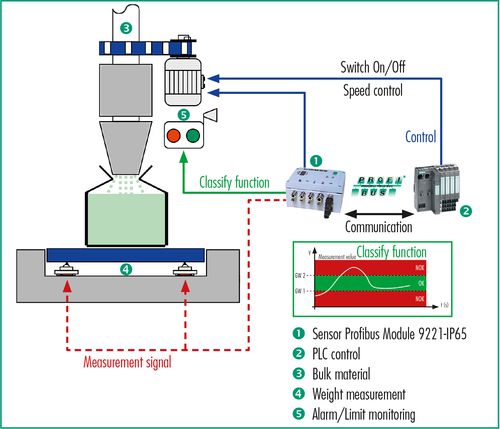

Weight measurement

on a fill facility with monitoring and controlling system

- Three switched outputs

- Can be used in harsh industrial environment

- High accuracy

TASK

The total weight at a fill facility should be determined and with a stopping mechanism activated when the system’s desired weight is achieved. The measurement values of the fill facility should be transferred with rank numbers and time to the paramount PLC Control (step 7) in order to enable further automation solutions.

SPECIFIC REQUIREMENT

With each new filling the dead weight of the receptacle should not be considered in the measurement of total weight. Thereby the tared value shall be accounted for with it in the background and also stored. The weight alterations shall be collected simultaneously through 4 parallel switched load cells and added to a total weight and evaluated.

SOLUTION

Four parallel switched and standardized load cells are connected to the efficient Sensor Profibus Module 9221-IP65, which also acts as power supply. The load cells are protected from process related disturbances like lateral forces. The module classifies different fill stands and abides by the user definable switch thresholds GW1 and GW2 at the exits A1 / A2 / A3. The Sensor Profibus Module generates the necessary switch signals, accurately regulating the supply of the bulk material. Distance taring operations take place from the PLC unit to the module. The measurement data collected (e.g. total value, tared value and evaluation status) on the other hand are provided for the paramount PLC control for data logging.

Sectors

Downloads